ASPN Tubes Pvt. Ltd adheres to 'Quality is the best quantity' and refuses to compromise on quality at any given point of time. We aim at consistently producing high standard stainless steel tubes and pipes conforming all the mutually agreed terms to our customers to ensure total customer satisfaction.

Soon, we have an in-house well-equipped testing laboratory to carry out the given procedures batch-wise to establish excellence in the output delivery.

All our quality control standards comply with the world standards because every being in ASPN Tubes Pvt. Ltd refuses to compromise on quality. We carry out several tests at different stages to ensure the highest standards in output delivery. We ensure regular supply and prompt delivery of the products and believe in long term association with our clients. Our team � the backbone of ASPN is well equipped in the field of stainless steel with extensive experience in manufacturing tubes. We are in a constant hustle to manufacture high-quality, cost efficient, easy-to-use products for our clients. At ASPN Tubes Pvt. Ltd, we are ready to walk the extra mile of hardship to serve our customers with the best.

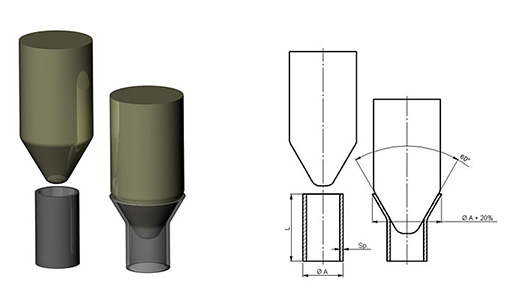

The basic procedure of this test involves a flare at the end of the pipe to a diameter of 1.2 times the outside diameter.

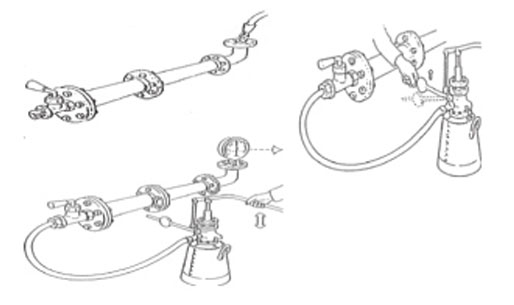

Hydraulic and Pneumatic systems are used to carry out 100% hydrostatic on all pipes and tubes as per ASTM standards.

This test is carried out on the entire length of the tube as per ASTM E-420 to determine the sub surface in homogeneities. However, this test is carried out on demand only.

This test being carried out on demand is as per ASTM E-426 to determine the substance in homogenities.

This test is mostly executed for �Y� tubes on specific demands.

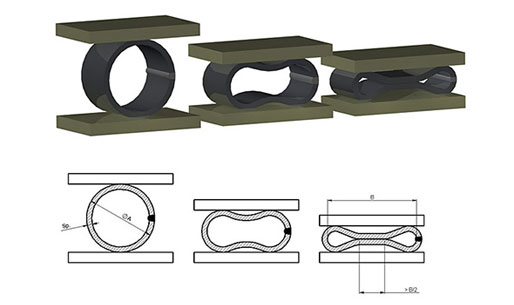

This test is carried out to check the strength of the welded section of the tubes or pipes it to extreme compression stress.

Cracks or blow holes are not observed on the welded.

Cracks or blow holes are not observed on the welded section.

There are no cracks observed on the welded section or on the base metal.